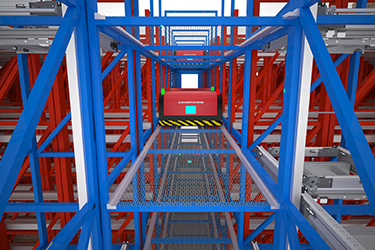

Automatic Storage Retrieval (AS/RS) Systems

Automated Storage & Retrieval Systems are one of the most reliable and successful material handling investment options currently available.

Armstrong’s Automated Storage and Retrieval Systems(AS/RS), have the ability to sort, sequence, buffer, and store a wide range of goods into virtually unlimited destinations which makes it an indispensable warehouse automation technology. Common applications for an ASRS include goods to person picking, dynamic replenishment, sequence buffering, order fulfillment, work in process storage, and finished goods storage.

Armstrong - India’s leading warehouse automation company understands the need of the market players to conserve floor space, improve safety, and boost productivity within the warehouse facility. Thus, our systems generally replace vast expanses of shelves and help in establishing air rights. Thanks to the incremental system design, ASRS Systems can easily expanded to meet increasing productivity demands.

Stacker cranes are the perfect pick for your unit loads and high bay facilities. Stacker-crane systems with guide rails and control systems perform distance travel, lifting, picking, and placing operations. It is made up of telescoping forklifts and makes your operations quick and error-free, which can easily be controlled by operators. The Unit-Load AS/RS systems from Armstrong enable safe, high-density, and energy-efficient storage for pallets and other bulky items.

Key advantages of the Unit Load AS/RS System:

- High Density Storage

- Quick Access Coupled with Minimum Labour

- Dependable, Precise & Efficient

To positively transform your business use Armstrong’s AS/RS technology that helps you achieve the lowest cost storage density and offers the highest throughput.

FAQ's

AS/RS systems comprises of a number of computer-controlled systems for placing and retrieving loads from predetermined storage sites.

AS/RS systems are of two types - Unit Load & Mini Load.

AS/RS reduces costs by reducing the amount of redundant parts and items in a warehouse. It decreases human involvement in operations, thus lowering overall operational costs and at the same time improving safety & ergonomics.

A number of factors determine the need of the AS/RS technology in your warehouse. Your capacity to deploy a system could-be influenced by the factors such as business cycle, operational goals, level of growth, and available investment resources. We recommend you to speak to our expert consultants to find a suitable solution that fits your requirements.