How Should You Select The Right Vertical Conveyors For Serving Your Purposes?

Is there any trouble or situation bothering your transportation work at your warehouses? Well, the time has come to find the right solution to your problem. Yes, you can get the best products here.

Armstrong LTD. is a franchise that provides the best Vertical Conveyors in affordable pricing.

Do you find trouble with different working methods? Well, the use of these conveyors will give you a stress-free working environment. Selecting our brand's products can give you many advantages in different aspects.

Higher Product Values and Multiple Possibilities with Armstrong LTD.

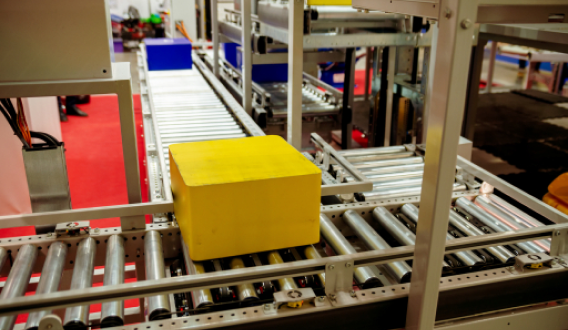

It is useful to use Vertical Conveyors for different types of working situations over warehouses. Who doesn't love the work of machines with efficiency and better time-saving strategies?

That is why many warehouse owners and other small or micro business firms prefer the use of these conveyors as their primary transportation units for their products. These conveyors use different apparatus for functioning correctly.

The primary equipment that brings life to the conveyors is the use of chutes, buckets, carts-on-track, belts, screws, and other technology in conveying divisions.

The name is given to this conveyor as a vertical apparatus because it is based on the vertical movement of transportation technology. Using these conveyors, you can manage to transport products either up or down in elevation.

Why Do Smart Warehouses Prefer These Conveyors?

It is not so hard for us to explain the higher utilities of Vertical Conveyors. Armstrong LTD. Has done a tremendous job in the manufacturing of such types of products for modern warehouses.

Many benefits are there using this system as the primary unit of your warehouse. No other options are available for you to handle at your warehouses better than these conveyors.

Are you ready to go with this product? Well, it is totally upon you and your selection of advanced machinery for your warehouses. The company does provide multiple varieties that may be the right option to go with.

However, you should conduct some general inquiries before setting your targets. Using these conveyors can give you the following benefits:

- Use to carry products vertically

- Consume smaller space in your working areas

- Easily manageable

- Automatic transmission

- Carry heavy products to higher altitudes

- Avoid human resources

- Better efficiency

- No time consuming

This is why the majority of warehouse owners prefer the use of Vertical Conveyors. They know that using such advanced apparatus can bring the best efficiency in the working environment.

No Trouble Exists When Use Such Conveyors - Contact Us Now!

There is no need to panic or be curious about finding the right transportation system in the vertical direction at your warehouses. The solution is right here. We provide the best support for your company in different aspects.

You should know all details and their applications in the industrial sectors. Many prefer the use of these conveyors as the best and valuable part of their working unit. So, without wasting your time, collect the best applications of this equipment:

-

Packaging stations

These conveyors are used to create packaging and processing lines at production houses.

-

Sorting inspected parts

As fixed by the algorithm, the system decides to sort all products one by one. Using such a process, this type of conveyor is suitable

-

Inspection systems

These conveyors carry all goods to the inspection systems, where the entire process is to check all qualities of products and pick out unwanted or faulty ones.

-

Assembly lines

Robots are there to do all their work as a feeding conveyor carries all the goods in the systematic order. These conveyors help all items to assemble at one specific place without changing the course.

-

Workstations

When items come out from automated sorters, these conveyors play the best part. Without the presence of an operator, they can carry all goods to the desired place without any trouble

-

Palletizers

The relationship between robotic palletizers and conveyors is not new. Automated operations like distribution and transportation in different warehouses are possible using these two unique apparatus.